An example of a pharma application

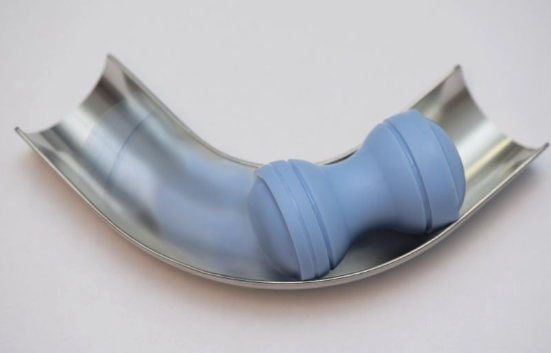

An example of a pharma application, actually in this case an URESH double pigging system, when the pig is used as a valve in the pigging line. The advantage of avoiding vales in the pigging line is reduction of the contamination risk.

A typical application example

A typical application example for pigging is the production of baby food: The need for safe batch separation, cleanability without dead spots with CIP ( even possibly SIP) allowing a quick turnover from one small batch to the next small batch volume. Words of one plant manager “because we had …

Most important effects you experience with pigging in production:

– Reducing time for cleaning (CIP, SIP), because with an oversized pig there is less than 0.1mm product/propellant mix left in the pipe, even in all bends!– Increased product quality due to better cleaning (proven with baby food application).– Reduced amount of produce needed for more end product, because no …

Pigging technology offers

Pigging technology offers any liquid/semi-liquid product manufacturer numerous opportunities to optimize their processes, based on a very simple principle. The geometry of the pig is precisely matched to the respective pipe diameter and bends. This creates a seal in the pipe and no medium can flow past it (no liquid, …

Thinking about pigging?

Use the original URESH pigging system. For processes up 140°C, hygienic, sterilization with steam, perfect for the pharma and food production.#pharma #food #production #productionoptimization #sustainability #reducewaste #reducereuserecycle

Pigging in Pharma/Biotech

Most assume that typically a pigging application focuses on food or cosmetics production, but in reality URESH pigging systems are used in many biotech or pharmaceutical production as well. Standards for cleanability, no contamination and clear batch separation is a given for production, but as well experience in URS standards …

Most important influences you experience with pigging in production

Decreasing time for cleaning (CIP, SIP), because with an oversized pig there is less than 0.1mm product/propellant mix left in the pipe, even in all bends!Increased product quality due to better cleaning (proven with baby food application).Reduced amount of product needed for more end product, because no manufactured product is …