Pigging is known as the solution to reduce waste, but less often considered for the reduction of energy use and water. Substantial amounts of water for cleaning – CIP or SIP – can be saved in a simple and easy way. Here is the Video

Stop and restart the pig at any time, anywhere in the pipeline

Only with the URESH pig it is possible to stop the pig anywhere, even in the bends and to continue again the pigging process without pulsation. It is clearly shown here Here is the Video

How does the pig travel in a bend?

Thanks to the glass pipe URESH makes it possible to see how the pig travels in the pipe and in the bend, as well as how the product is completely discharged. Here is the Video

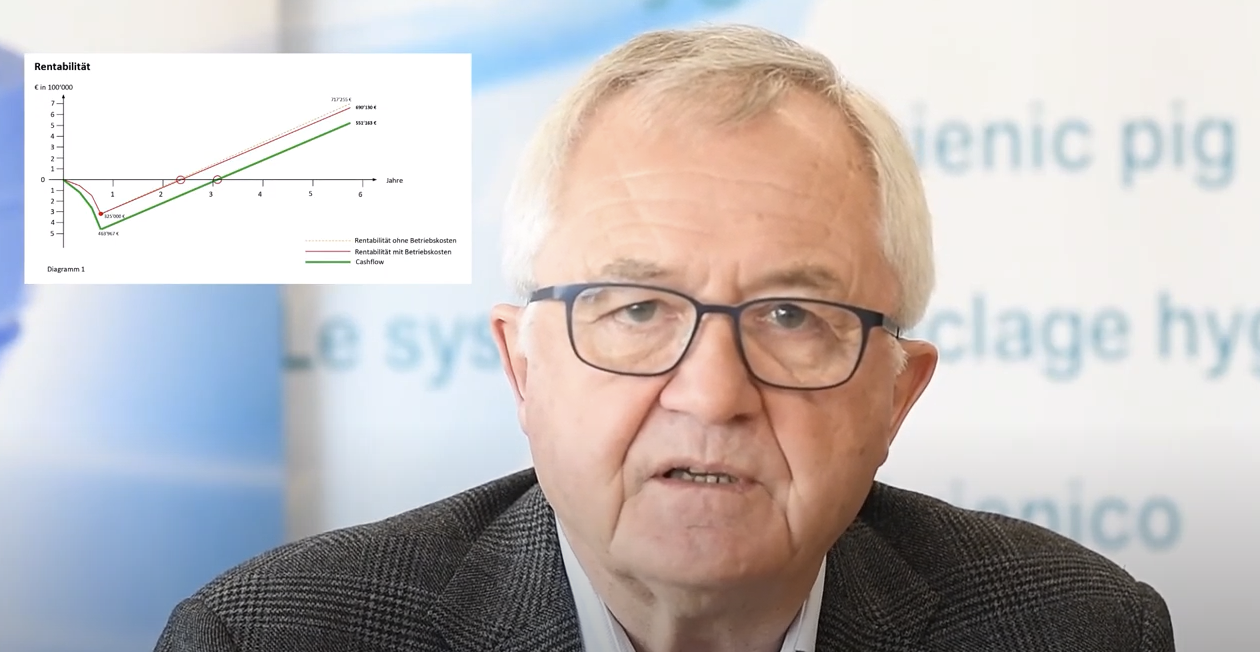

The profitability of a pigging system

Examples from praxis show that an investment of a pigging system is worthwhile and the investment costs are easily paid back within 8-14 months by the savings in product, rinsing costs and time. Here is the Video

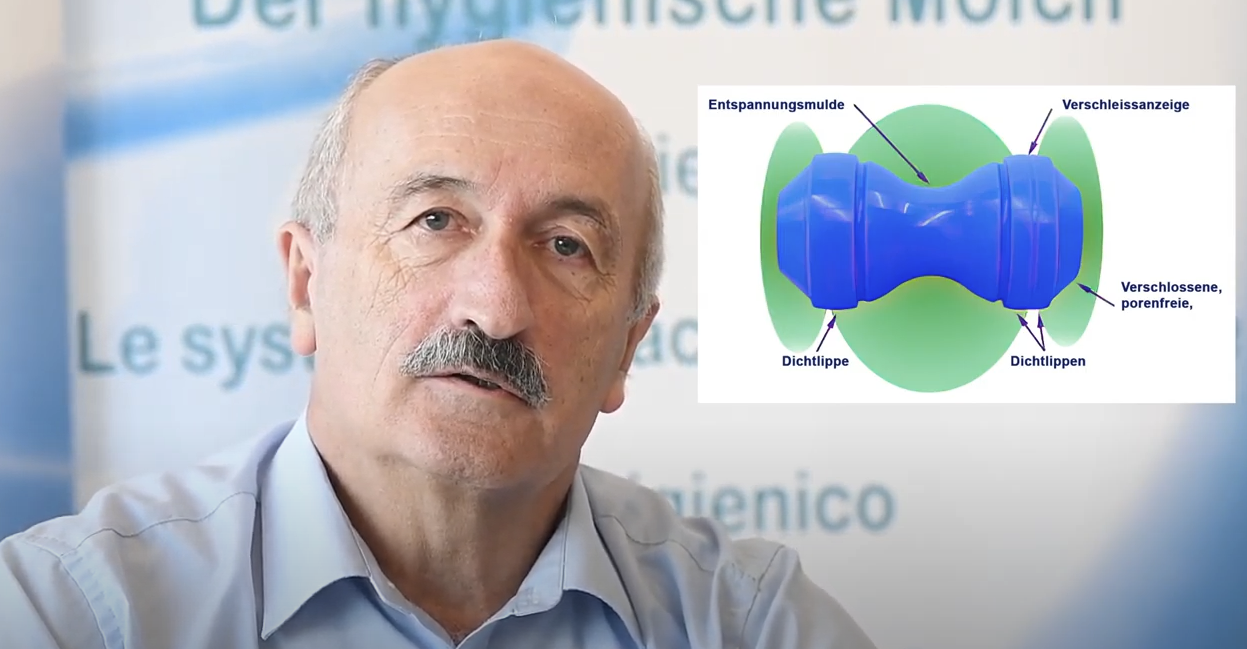

SIP application and EHEDG certification of the URESH pig

The patented form of the pig is clearly evident by the behavior in the bends, as well as the possibility to stop and restart the pig at any point in the pipe. Furthermore, the pigging system can be completely sterilized up to 140°C for SIP application. Here is the Video

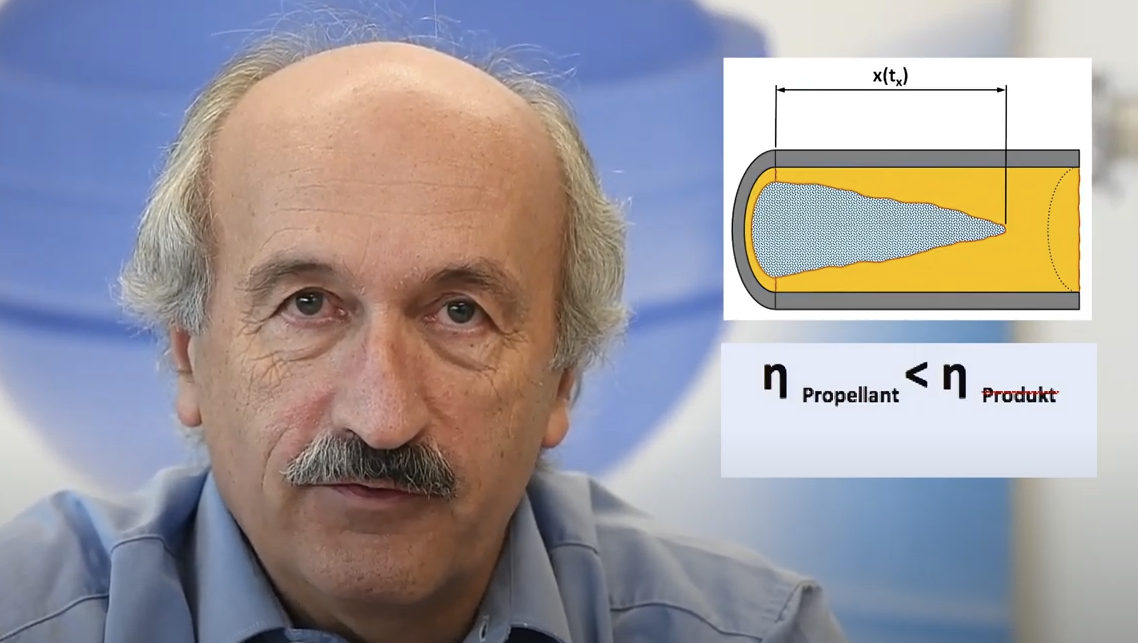

Discussion about the technical aspects of the URESH pig

The pig contributes strongly to operational safety, product recovery and batch separation. What makes the URESH pig unique is explained by the founder of URESH Urs Hofer. Here is the Video

New series on the technical aspects of pigging

The founder of URESH, Urs Hofer, has years of extensive experience in the application of pigging. With a series of videos, the technical aspects of pigging are highlighted. The first clip answers the question why pigging? Here is the Video

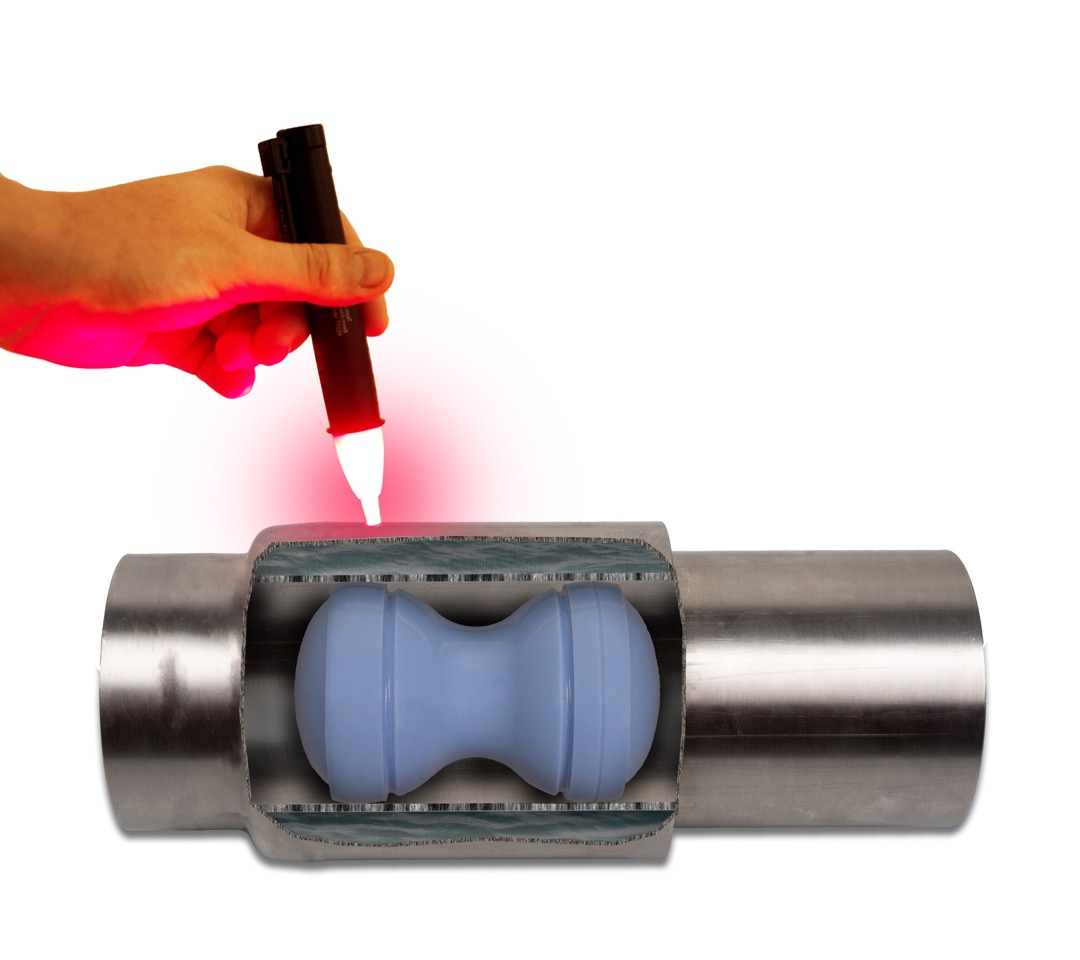

Straightforward detection of the pig in a double-walled pipeline

Detecting the pig easily and quickly in the pipeline is the basis for safe operation of a pigging system. The URESH pigging system is designed in such a way that the pig with the cast-in magnets is clearly indicated by a magnetic sensor even in double-walled pipelines (cooling or heating …

What happens when cocoa or chocolate lines are not pigged…

It is well known that cocoa or chocolate should not come into contact with water during production, but is often forgotten what really happens, if the pipes in production are not emptied. If cocoa or chocolate is not cleared in the pipes, the whole mixture turns into a rock hard …

ProSweets from 2-5 February 2020 in Cologne

URESH AG will participate in ProSweets in Cologne from 2-5 February, the international supplier fair for the confectionery and snack industry. Why the chocolate industry prefers the URESH pigging system over all other systems will be demonstrated in hall 10.1 at stand E040. Find out more about this unique, state-of-the-art …

URESH Pigging System Symposium 2019

On 10 September 2019 the third URESH Pigging System Symposium took place in Düsseldorf, Germany. It was held in the industrial plant originally built in 1910 and administered by the Hans Peter Zimmer Foundation. At that time it was used by the Consumverein for the production of bakery products. Sibylle …

CIBUSTEC 22/25 October 2019 Parma Italy

We are looking forward to welcoming you at CIBUSTEC in Parma from the 22nd to the 25th October. In the Hall 03 at the boot E043 we will show you live at the pigging station why our unique technology is preferred by several beverage and food manufacturers. You don’t …